A friend and I are exploring the potential of our hackerspace’s new multi-material 3D printer for creating custom footwear. While it seems like an ideal match for our needs, I’ve hit a critical roadblock—finding the right materials. Specifically, I need extra grippy rubber soles for my oversized feet, but the type of rubber typically suited for such applications can’t be 3D printed.

In my quest for answers, I reached out to a petrochemist friend to inquire about the melting points of various rubbers. His insights revealed that there’s no simple solution, as rubber behaves differently from the common polymers used in 3D filament. With standard plastic materials, the filament can be heated until it liquefies and flows out of the extruder, solidifying into shape upon cooling. This is where the term “plastic” originates, indicating the material’s moldability.

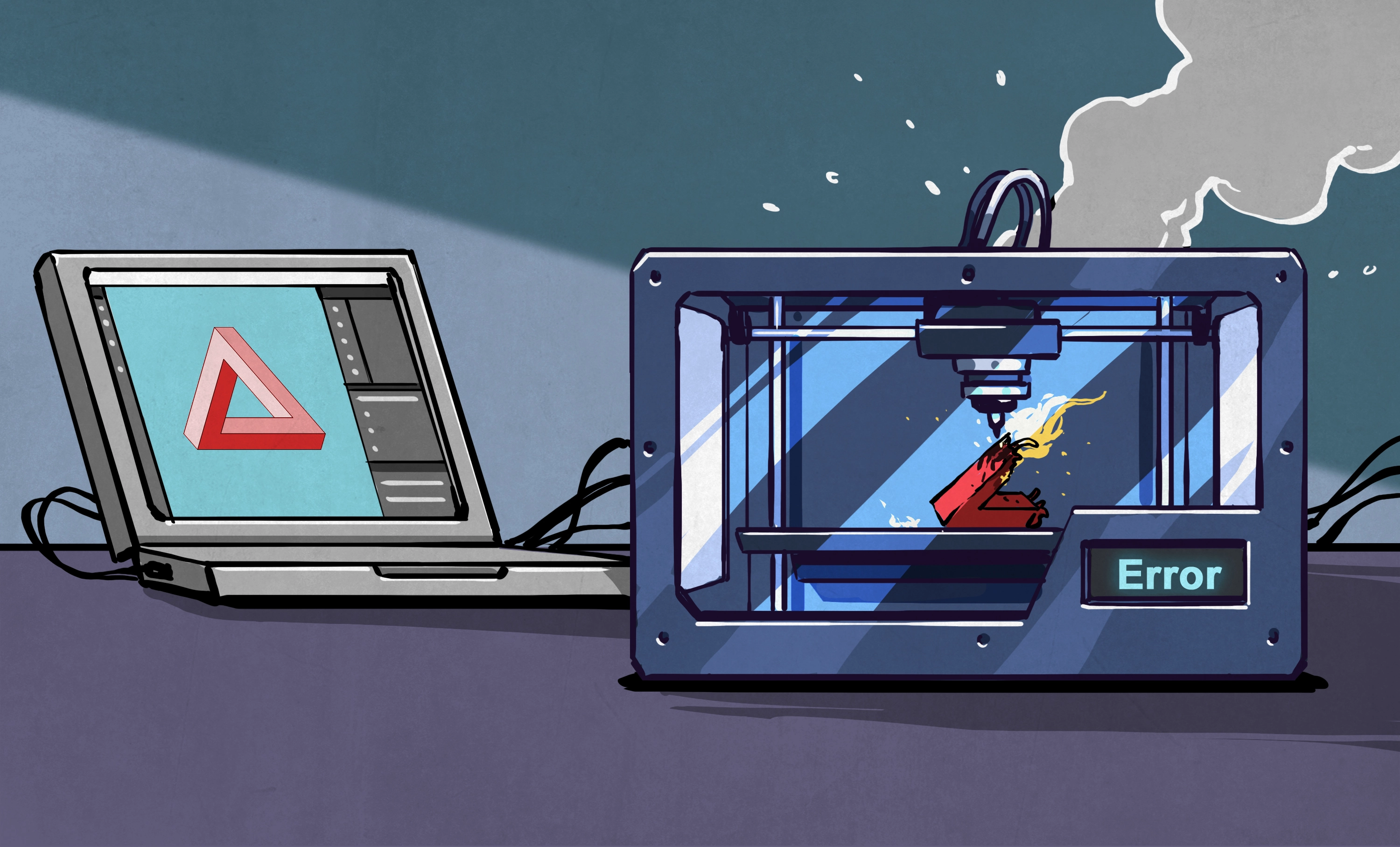

Rubber, however, is a non-Newtonian fluid, meaning its viscosity changes under pressure. This characteristic means that, unlike traditional filaments, rubber does not neatly liquefy and flow. As I learned, if I tried to extrude rubber filament through my printer, it would become excessively viscous and potentially clog the nozzle. While Thermoplastic PolyUrethane (TPU) presents some flexibility, it’s not truly rubber and lacks the same grip.

So, if rubber can’t be directly 3D printed, how are rubber products usually made? I discovered that rubber molding processes typically involve pressing shredded rubber into molds and applying heat, which fuses the rubber without needing excessive temperatures. This revelation opens up new possibilities—perhaps it’s feasible to replicate this process in a hackerspace setting.

As I continue working on the multi-material uppers, I’m left contemplating the challenges rubber presents for 3D printing. It seems that while my footwear ambitions may be temporarily thwarted, the journey into the world of polymers and manufacturing techniques is just beginning. Has anyone out there explored printing with real rubber?