Aluminum is recognized for its versatility, praised for its lightweight and strong properties. However, its performance suffers significantly under high temperatures, a drawback particularly evident in aerospace and automotive sectors where parts like turbines and engines require enhanced thermal resistance.

To tackle this issue, researchers at Nagoya University in Japan have engineered a new range of aluminum alloys via metal 3D printing, aimed at improving mechanical strength and heat tolerance. These new alloys utilize low-cost, commonly available elements and are recyclable. Notably, one of these alloys retains both strength and flexibility even at temperatures as high as 300°C. Their findings were published in Nature Communications.

Creating the Optimal Alloy

The researchers devised a method to predict which elements would bolster the aluminum matrix and which could create protective micro- or nanostructures. They confirmed their predictions by developing new alloys incorporating copper, manganese, and titanium.

The standout alloy comprised aluminum, iron, manganese, and titanium, outperforming its counterparts by merging high-temperature strength with room-temperature flexibility. Traditionally, iron is avoided in aluminum alloys due to its tendency to render the material brittle; however, Professor Naoki Takata, the study’s lead author, emphasized a unique design focusing on iron which redefined its interaction with aluminum.

Redesigning Aluminum’s Internal Structure

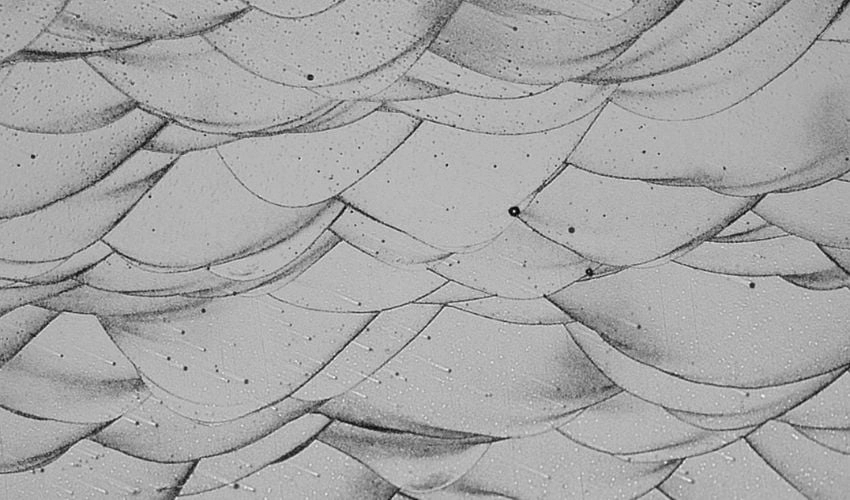

This innovation leverages laser powder bed fusion technology, allowing for the entrapment of iron and other elements in metastable forms, a feat unattainable through conventional manufacturing methods. The team’s systematic approach led to the identification of elements essential for reinforcing the aluminum matrix while enhancing its structure at high temperatures without hindering the printing process.

The resultant alloys maintain lightness and robustness at elevated temperatures, combining mechanical strength with ductility. Importantly, all materials are made from low-cost, recyclable resources, making them both technologically advanced and environmentally friendly.

Professor Takata remarked that their method draws from established scientific principles regarding rapid solidification in 3D printing, applicable to various metals. These alloys simplified the 3D printing process compared to traditional high-strength aluminum, which is often prone to cracking or warping.

Environmental Benefits and Industry Application

This advancement not only promises lighter vehicles and lower emissions but also the production of high-performance components designed for high-temperature conditions, particularly in automotive and aerospace applications. The low-density aluminum components could revolutionize the design of critical parts like turbine components and compressor rotors.

The aerospace industry stands to gain significantly, as aircraft engines demand materials that successfully integrate lightweight design with heat resistance. The research sets a foundation for engineering new metallic classes tailored specifically for 3D printing, potentially fast-tracking advancements across various industrial landscapes.

What are your thoughts on the new aluminum alloys from Nagoya University? Engage with us in the comments or join the conversation on LinkedIn or Facebook. Stay informed by signing up for our weekly Newsletter for the latest in 3D printing news.