As 2025 comes to a close, 3Dnatives reflects on the key trends shaping the additive manufacturing industry over the past year. This period has been marked by technological maturation, market reconfiguration, and increased real-world applications.

In 2024, the additive manufacturing sector faced challenges due to disputes among major players, such as Stratasys and Bambu Lab’s legal battles, and Nano Dimension’s acquisitions of Desktop Metal and Markforged. However, 2025 saw a stabilization period where certain applications proved their viability, leading to a more defined industry landscape.

Natural Selection in the Additive Manufacturing Market

Significant corporate restructuring characterized 2025, particularly highlighted by Nano Dimension’s acquisition of Desktop Metal and Markforged. Legal disputes complicated the process, especially for Desktop Metal, which filed for Chapter 11 bankruptcy to address its debt. Despite these challenges, Nano Dimension reported business growth, largely due to its acquisition of Markforged.

In contrast, BCN3D Technologies faced insolvency but was acquired by Quantum, which aims to streamline operations and focus on light industrial applications. Another significant exit from the market was Arburg, which withdrew from additive manufacturing to concentrate on its core injection molding business.

These changes emphasize an ongoing reorganization phase within the industry, suggesting that not all players can adapt equally.

The Diversification of Major Manufacturers

Established manufacturers like Stratasys, HP, and Raise3D expanded their portfolios, entering new technologies and materials. Stratasys partnered with Tritone Technologies to move into metals and ceramics, responding to customer demands from sectors such as defense. HP launched its first industrial filament 3D printing platform designed for high-temperature materials. Raise3D introduced an SLS printer to broaden its offerings.

These strategic expansions reflect a broader trend toward comprehensive solutions, allowing manufacturers to cater to diverse additive manufacturing needs.

The Rise of the Chinese Market

China emerged as a formidable force in the 3D printing industry in 2025. At major events like Formnext, the presence of Chinese manufacturers continued to overshadow that of American companies. Bambu Lab, in particular, gained attention with the launch of advanced desktop 3D printers, helping make the technology more accessible and appealing to various demographics, including educational settings.

The quality and innovation from Asian manufacturers are now on par with traditional players, particularly in industrial segments.

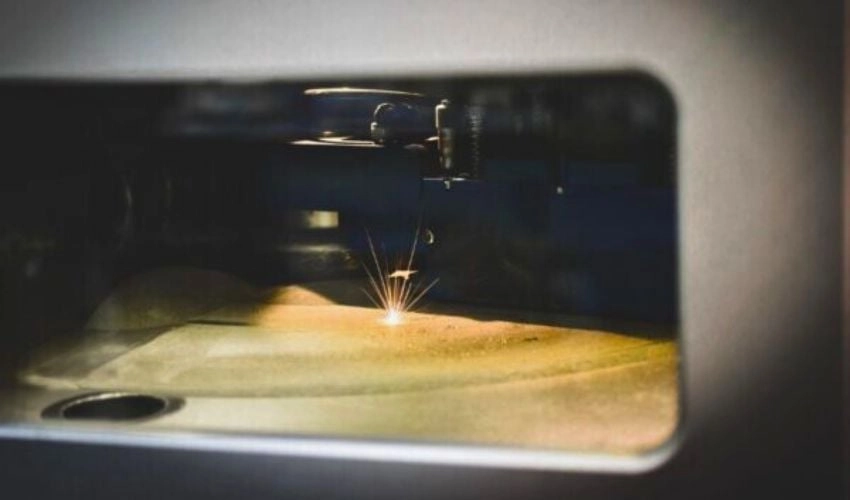

Technological Maturity in Critical Sectors

The defense and aerospace sectors have moved beyond experimentation, integrating additive manufacturing into real-world applications. With geopolitical tensions rising, defense budgets increased, leading to a surge in industrial 3D printer acquisitions. The recent National Defense Authorization Act in the U.S. affirmed the importance of additive manufacturing in defense, establishing it as critical infrastructure subject to stringent regulations.

In the aerospace sector, additive manufacturing is now used in producing components like rocket engines, exemplifying the technology’s maturation and application in demanding fields.

Contrasts Across Sectors

2025 also showcased disparities within different sectors of additive manufacturing. While research in 3D food printing has slowed, construction emerged as a growing field, with companies focusing on sustainable materials and practices. Caracol, an Italian startup, raised significant funding aimed at expanding internationally, highlighting these shifts.

As 2025 concludes, the additive manufacturing industry stands at a crossroads of maturity and transition, laying the groundwork for future innovation and adaptation. The ongoing developments will be closely monitored as the industry tailors its solutions to meet evolving industrial needs.