As Japan faces an increasingly aging population and a shrinking construction workforce, Shimizu Corporation is responding with an innovative approach to 3D printing. The company has developed a spray-based system aimed at fabricating large, complex, and reinforced concrete structures. This technique diverges from traditional extrusion-based 3D printers by utilizing a specialized nozzle to spray a concrete mixture, enabling the creation of shapes that conventional methods struggle to achieve.

One of the significant advantages of this spray-based system is its ability to deposit concrete from various angles, effectively working around steel reinforcement cages. This flexibility is crucial, especially in seismic regions where reinforced concrete is essential. Traditional concrete printers often face difficulties when dealing with rebars, but this new method successfully eliminates those limitations, paving the way for more versatile and robust structural construction.

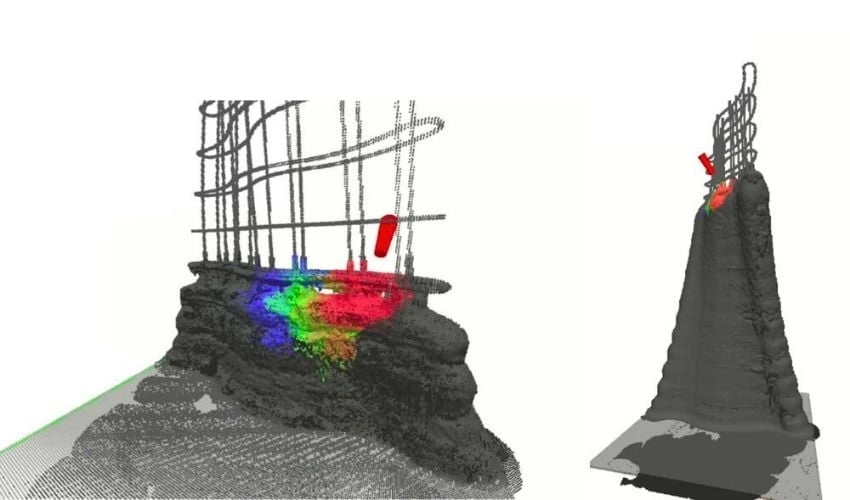

To address the challenges of spraying concrete, such as material rebound and drip due to various factors like nozzle distance and angle, Shimizu has collaborated with Carnegie Mellon University’s Computational Engineering and Robotics Lab to create a material spray simulator. This software predicts how the concrete will behave when sprayed, allowing engineers to optimize tool paths, spray angles, and speeds prior to actual printing. Such foresight helps minimize defects and waste, ensuring that the printed shapes align accurately with the intended digital designs.

The printing system employs a sophisticated setup that merges a seven-axis robotic arm with a two-axis gantry, providing it with nine degrees of freedom. It operates within a spacious build volume measuring six meters deep, four meters wide, and three meters high, allowing the nozzle to spray in multiple directions, including within dense reinforcement cages. A recent demonstration illustrated this capability when the robot successfully produced a twisted concrete wall standing 2.5 meters tall within just four hours, affirming the system’s proficiency in handling complex geometries on an architectural scale.

For Shimizu Corporation, this technology is crucial as the need for automation grows in the construction sector. The spray-based 3D printing method not only reduces the reliance on manual labor but also expands the creative possibilities for architects and engineers working with reinforced concrete.

To learn more about Shimizu’s innovations in concrete 3D printing, you can visit their page here.